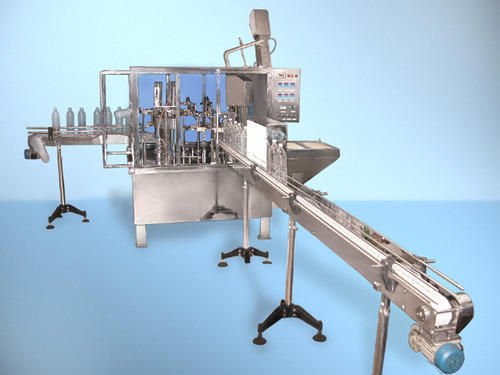

Fully Auto Pet Bottle Rinsing Filling and Capping Machine

600000 INR

Product Details:

- Product Type Fully Auto PET Bottle Rinsing Filling and Capping Machine

- Material Stainless Steel (SUS304/316)

- Application Beverage, Mineral Water, Juice, Soft Drink, Non-carbonated Drinks

- Packaging Material PET Bottle

- Computerized Yes

- Automatic Grade Fully Automatic

- Control System PLC Control with HMI Touchscreen

- Click to view more

X

Fully Auto Pet Bottle Rinsing Filling and Capping Machine Price And Quantity

- 1 Piece

- 600000.00 - 1500000.00 INR

- 600000 INR

- <70 dB

- 6

- Stainless steel bottle conveyor with adjustable speed

- 0.6-0.8 MPa

- Automatic vibrating cap feeder

- 12

- 12

- Reverse bottle water spraying

- 1 (for monitoring and maintenance)

- 200 ml - 2 L

- Quick changeover for different bottle sizes

- ±1%

- 3.5 kW

Fully Auto Pet Bottle Rinsing Filling and Capping Machine Product Specifications

- ~1800 kg

- Yes

- Fully Automatic

- Beverage, Mineral Water, Juice, Soft Drink, Non-carbonated Drinks

- 2200 mm x 1600 mm x 2400 mm

- Stainless Steel (SUS304/316)

- PET Bottle

- 220V/380V, 50/60Hz

- Silver/Gray

- Fully Auto PET Bottle Rinsing Filling and Capping Machine

- Electric

- PLC Control with HMI Touchscreen

- 3000 - 10000 bottles per hour (depending on model and bottle size)

- Automatic operation, high-speed performance, integrated rinsing, filling, capping, easy maintenance

- <70 dB

- 6

- Stainless steel bottle conveyor with adjustable speed

- 0.6-0.8 MPa

- Automatic vibrating cap feeder

- 12

- 12

- Reverse bottle water spraying

- 1 (for monitoring and maintenance)

- 200 ml - 2 L

- Quick changeover for different bottle sizes

- ±1%

- 3.5 kW

Fully Auto Pet Bottle Rinsing Filling and Capping Machine Trade Information

- 10 Piece Per Month

- 1 Months

Product Description

Nishu Enterprises can be your trusted partner in sourcing fully auto pet bottle rinsing filling and capping machine at market leading price. It can work with PET plastic bottles in different sizes for filling water, fruit juice, sauce and many other food products in the form of liquid and paste. The bottle handling system of this machine operates from bottle neck, which eliminates the need to adjust the height based on the bottle size. The operator once set up the machine it operates independently, filling consistent net content without spillage. The components of the machine that contact with the food are made of stainless steel. The operations of the fully auto pet bottle rinsing filling and capping machine are PLC controlled and there is VFD for speed control.Key Points:

1) It is possible to adjust the filling capacity and output of the machine.

2) The caps are UV sterilized.

3) If there are no bottles on the conveyor, the spray mechanism automatically stops and saves water.

4) The machine has a central lubrication system.

Integrated and Efficient Workflow

This machine streamlines the bottling process with automatic rinsing, filling, and capping in one compact unit. Its reverse bottle water spraying method guarantees hygienic rinse, while the vibrating cap feeder keeps operations continuous. The PLC touchscreen offers easy control of speed and settings, making it suitable for beverage manufacturers seeking reliable automation.

Versatile Bottle Handling and Quick Changeover

Accommodating PET bottles from 200 ml up to 2 liters, the system allows rapid changeover for different bottle sizes thanks to user-friendly adjustment mechanisms. The stainless steel conveyorwith adjustable speedensures smooth bottle transfer, while robust materials support applications in mineral water, juice, and soft drink bottling.

Precision and Quality Assurance

Engineered for filling accuracy within 1%, this machine maximizes product yield and reduces waste. The advanced PLC control system provides real-time monitoring and diagnostics, minimizing downtime and supporting consistent, high-quality output even at peak capacities.

FAQs of Fully Auto Pet Bottle Rinsing Filling and Capping Machine:

Q: How does the machine enable automatic bottling from rinsing to capping?

A: The machine integrates reverse bottle water spraying for rinsing, precise filling via 12 heads, and reliable capping using 6 heads in a seamless automated workflow. The PLC touchscreen allows easy monitoring and adjustments, while the vibrating cap feeder ensures uninterrupted cap supply during operation.Q: What types of products and bottle sizes can be processed on this machine?

A: It is suitable for packaging beverages, mineral water, juices, and soft drinks in PET bottles between 200 ml and 2 liters, making it versatile for various non-carbonated drink manufacturers.Q: When should a manufacturer consider using this machine?

A: Manufacturers seeking high-speed, fully automated bottling lines for quality control, efficiency, and reduced labor should deploy this system, especially if they require up to 10,000 bottles per hour output and quick changeovers between bottle sizes.Q: Where is the machine commonly installed and operated?

A: This machine is typically installed in beverage production facilities, water bottling plants, and juice manufacturing units. Its adaptability and compact footprint make it suitable for both large-scale exporters and suppliers in India or abroad.Q: What process ensures accurate and hygienic bottle filling?

A: The reverse water spraying rinsing system cleans bottles before filling, and the 12-head filling system delivers product with 1% accuracy. Stainless steel construction and automated cap feeding further assure hygiene and consistency throughout the packaging process.Q: How is maintenance and operator involvement managed?

A: The machines fully automatic features minimize manual intervention. One operator is required mainly for monitoring and occasional maintenance, facilitated by the HMI touchscreen, which offers real-time diagnostics to quickly identify any issues.Q: What are the core benefits of using this fully automatic bottling machine?

A: Key benefits include increased productivity, consistent product quality, reliable hygiene, reduced labor costs, quick adaptation to various bottle sizes, and easy maintenance, making it ideal for competitive beverage industry applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Water Bottle Filling Machine' category

|

NISHU ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese